NOX Tiltrotator for Excavator | NOX Sensors

With the NOXGeo, sensors send position data to the digital control at the NOXProp+ touchscreen in the driver‘s cabin. Thereby, the attachments are connected to the digital technology of the excavator/ machine control. The NOXGeo system also allows the functionality to interface with 2D/3D systems of all common manufacturers thanks to the open system.

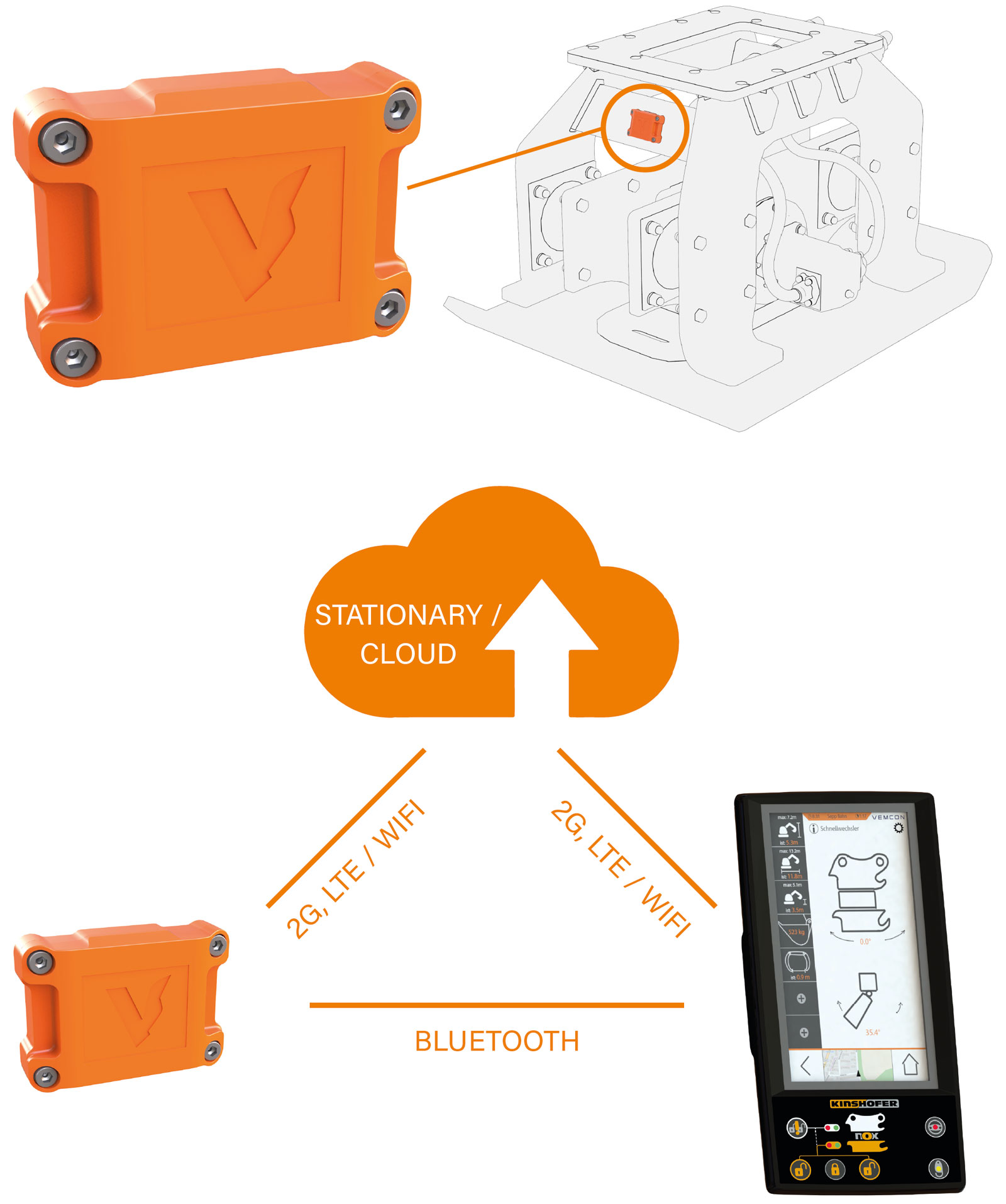

SmartTag Tool tracker

The SmartTag and the cloud-based tool management support the driver and operator with the efficient choice and detection of suitable tools for each special task. Operators have their complete fleet under control and thus avoid downtimes and maximize their tool workload.

The SmartTag combines two up to now separated functions in one sensor: tool detection and tracking. As digital type plate, the tool tracker files information on geometries, name, manufacturer, year, ID and operation (e.g. required operating pressure of attachment). At the same time, it gathers, analyzes and detects operating hours, cycles and work processes. Thansk to GPS position and timestamp, you receive data like when and where an attachment had been put down and how it had been used.

The SmartTag is a microcontrol-based tool with a communication functionality via mobile radio and an internal storage to locally back up operating information, error information, etc. The unit only measures 15 cm, it is waterproof, shock resistant, thermo-stable from -25 up to 80 °C, shockproof and has an internal energy supply for approx. 2 years.

Other NOX pages

Toplinks

KINSHOFER GmbH

Raiffeisenstrasse 12

83607 Holzkirchen

Tel.: +49 (0)8021 8899 0

Fax: +49 (0)8021 8899 37

info@kinshofer.com