HPXdrive for Crane | Technologies

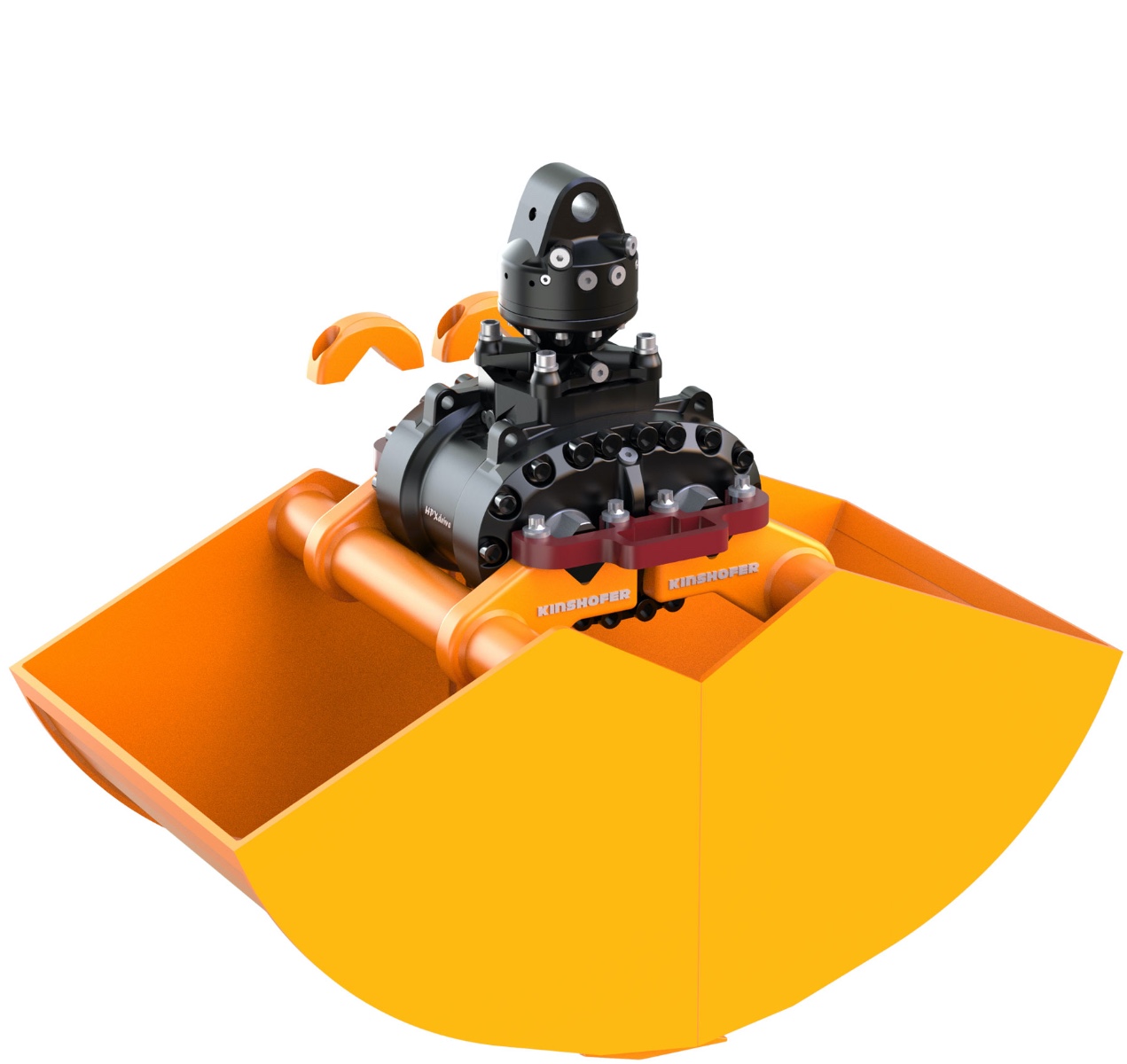

Functional exchange, depending on demands!

The HPXdrive Standard (SD) guarantees a secure working in daily tasks. Integrated pressure relief valves keep the operation independent from the carrier‘s operating pressure. The drive unit HPXdrive can be equipped with a standard flange rotator as well as with a shaft rotator. When used in combination with a shaft rotator, there are several options to connect the rotator with the drive unit, e.g. with our quick change device KM 505.

ALL SD-SHELLS ARE EXCHANGEABLE:

|

Type |

HPXdrive | Opening | Closing force | |||

| KM 604HPX | SD-module | 1390 mm | 19 kN | |||

| KM 626HPX | SD-module | 890 mm | 31 kN | |||

| KM 604U HPX | SD-module | 1590 mm | 17 kN | |||

| KM 613HPX | SD-module | 1200 mm | 18 kN | |||

| KM 632HPX | SD-module | 1220 mm | 18 kN | |||

| KM 641HPX | SD-module | 1190 & 1630 mm | 14 & 18 kN |

CUSTOMER BENEFITS:

FLEXIBLE OPERATION Fast and easy response to requirements, to be more competitive.

LOW MAINTENANCE The HPXdrive has no greasing point that need to be lubricated on a daily basis. Maintenance costs and time savings.

LESS WEAR The compact and extremely robust design, without hydraulic cylinders or short hoses, lowers risk of damages.

HIGHER EFFICIENCY More power thanks to the constant closing force during the entire gripping process. Tasks are finished faster and wear is kept to a minimum.

COMPACT DESIGN The HPXdrive has a compact and very robust design, no greasing points and, when mounted with a KINSHOFER rotator, short connecting hoses are no longer needed (internal oil feedthrough).

ALL HD-SHELLS ARE EXCHANGEABLE:

|

Types |

HPXdrive | Opening | Closing force | |||

| KM 605HPX | HD-module | 1420 mm | 30 kN | |||

| KM 605HPX-Z | HD-module | 1420 mm | 34 kN | |||

| KM 605U HPX | HD-module | 1545 mm | 28 kN | |||

| KM 605U HPX-Z | HD-module | 1545 mm | 28 kN | |||

| KM 613HPX-HD | HD-module | 1710 mm | 22 kN | |||

| KM 632HPX-HD | HD-module | 1290 mm | 31 kN | |||

| KM 641HPX-HD | HD-module | 1720 mm | 23 kN |

CUSTOMER BENEFITS:

FLEXIBLE OPERATION Fast and easy response to requirements, to be more competitive.

LOW MAINTENANCE The HPXdrive has no greasing point that need to be lubricated on a daily basis. Maintenance costs and time savings.

LESS WEAR The compact and extremely robust design, without hydraulic cylinders or short hoses, lowers risk of damages.

HIGHER EFFICIENCY More power thanks to the constant closing force during the entire gripping process. Tasks are finished faster and wear is kept to a minimum.

COMPACT DESIGN The HPXdrive has a compact and very robust design, no greasing points and, when mounted with a KINSHOFER rotator, short connecting hoses are no longer needed (internal oil feedthrough).

Exchange of shells with HPXdrive:

Thanks to the shell exchange system you lower your fleet investment costs.

CLOSING FORCE PROCESS (illustration)